At a project site in Chenzhou, Hunan Province, a fully upgraded polymetallic ore production line is now operating steadily and efficiently.

Just a few months ago, the scene was entirely different: dust accumulation was visible everywhere, leaving footprints in every step you took inside the workshop. All equipment was exposed to the elements, dust clouds hovered in the air, spare parts were scattered across the floor, and safety and environmental protection facilities were severely damaged. The equipment was covered in oil stains, leaks were common, and on-site inspections were conducted haphazardly, often with personnel standing or sitting on equipment without any safety precautions. The frequent equipment shutdowns required switching production lines, resulting in unstable production and output far below targets, significantly impacting production efficiency and profitability.

However, all of this changed dramatically, thanks to the meticulous renovation and maintenance services provided by Jiangxi Gold Intelligent Service Engineering Co., Ltd. (hereinafter referred to as “GIS”), a subsidiary of Nanchang Mineral Systems (NMS).

Workshop Before and After Maintenance

Workshop Before and After Maintenance

Responding swiftly to the customer’s needs, GIS assembled a team of senior engineers and technical experts who conducted a comprehensive on-site diagnosis. Through detailed inspections, the team accurately identified every issue and bottleneck in the production line. Soon after, a tailor-made maintenance plan was developed, focusing on safety, efficiency, and environmental protection.

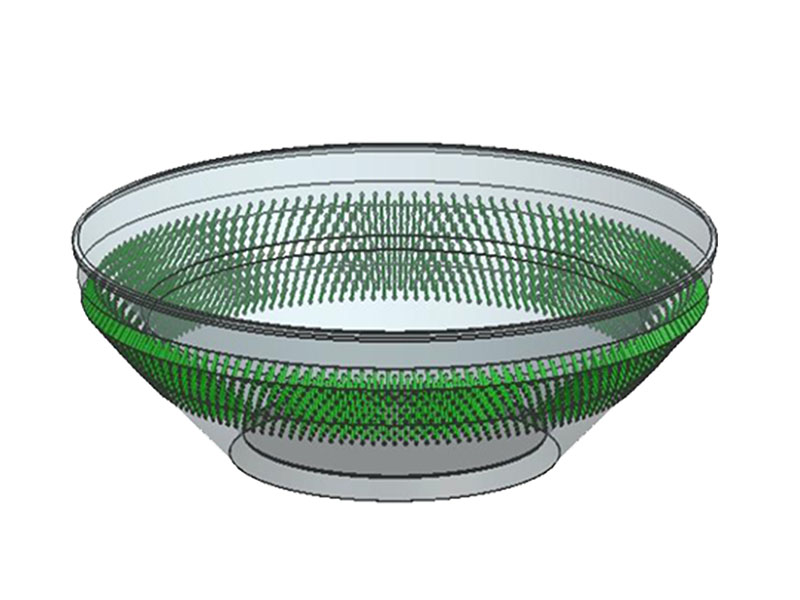

Screens Before and After Maintenance

Screens Before and After Maintenance

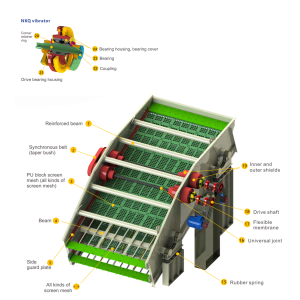

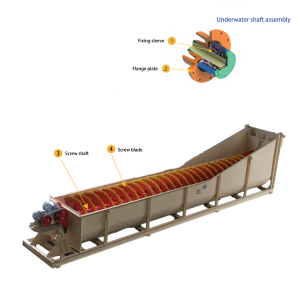

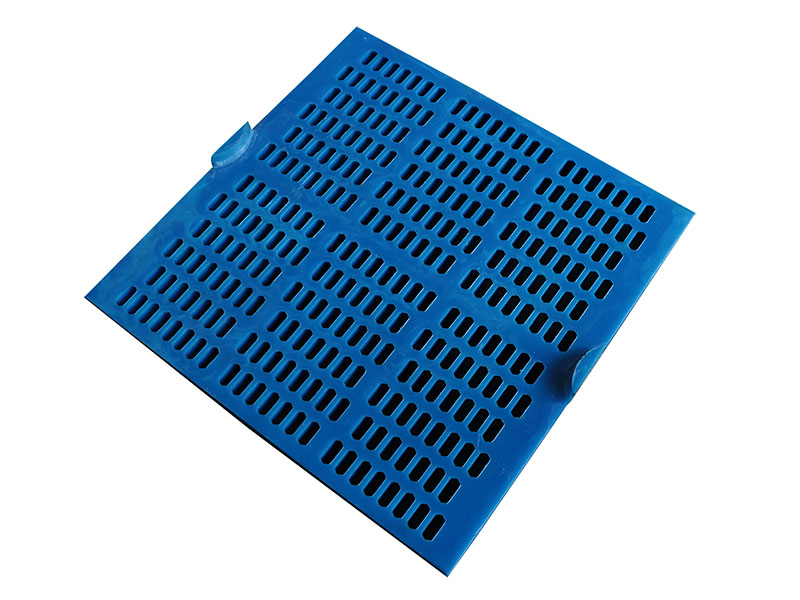

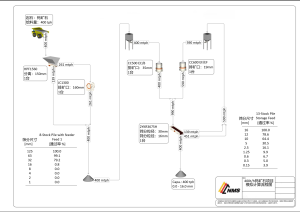

The maintenance team used NMS’s self-developed rock processing property tester to analyze the crushing work index and abrasion index of the granite containing copper, molybdenum, and tungsten from the polymetallic ore. By combining these raw material characteristics with the existing process, they redesigned the workflow using Flowsheet Designer, a process calculation software developed by NMS’s Swedish R&D center. The team dismantled and repositioned the unreasonably placed screens and added chutes to optimize the production process.

Project Simulation Flowchart

Project Simulation Flowchart

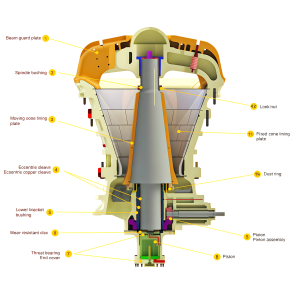

The maintenance team meticulously inspected and repaired issues with two jaw crushers, four cone crushers, two vibrating screens, and two bar feeders, all of which were plagued by oil and material leaks, hindering production efficiency. All aging and heavily worn parts were replaced as quickly as possible, helping restore stable production. Regarding uneven distribution and material accumulation in the screening machine, the team adjusted the mesh size, modified the feed hopper, and replaced spring pads. After multiple tests, they successfully increased the screening equipment’s hourly output from 270-300 tons to 350-370 tons, significantly exceeding pre-maintenance levels.

Given the high abrasiveness of the project’s materials, GIS optimized the equipment chamber design and improved the wear-resistant materials, significantly enhancing durability. The service life of the movable jaw plate increased from 90 to 140 working days, processing up to 500,000 tons of ore, while the fixed jaw plate’s life extended from 40 to 60 working days, processing approximately 250,000 tons of ore. The feeder bottom plate’s lifespan doubled to 4-6 months, and the replacement cycle for the bars extended from 20 to nearly 90 days. Furthermore, through innovative design and material upgrades, the lifespan of the cone crusher’s wear liners, previously replaced every 30 days, was extended to 55 days, processing approximately 240,000 tons of ore, reducing maintenance costs and improving overall production efficiency and economic benefits.

Maintenance Staff Replacing Cone Crusher Liners

Maintenance Staff Replacing Cone Crusher Liners

Maintenance Staff Replacing Jaw Plates

Maintenance Staff Replacing Jaw Plates

On the environmental front, the team installed dust covers and sealed off multiple dust points, upgrading the dust collection system and fans, effectively controlling dust emissions and significantly improving environmental conditions. Additionally, all old and disorganized electrical wiring was rectified, the oil stations and control rooms were overhauled, new safety platforms were installed above the motors, safety barriers, covers, and anti-slip strips were added, and a new warehouse was built. All safety hazards were eliminated, ensuring a secure production environment.

Efficient Use of Space for New Warehouse Construction

Efficient Use of Space for New Warehouse Construction

A major highlight of this maintenance effort was the comprehensive electrical system overhaul. Leveraging NMS’s intelligent operation and maintenance management platform, GIS achieved one-click start/stop functionality, remote monitoring, load optimization, fault warning, and automatic diagnostics, reducing labor costs and improving response times and efficiency. This provided more scientific and timely data support for maintenance decisions, helping the production line run more smoothly and efficiently, ultimately enhancing quality, reducing costs, and increasing efficiency.

Monitoring Interface of the Project’s Intelligent Operation and Maintenance System

Monitoring Interface of the Project’s Intelligent Operation and Maintenance System

These comprehensive maintenance measures transformed the production line: the hourly output increased from under 300 tons to 350-400 tons. The line now runs about 12 hours daily, eliminating the need for backup lines, significantly reducing operating and maintenance costs. Equipment failure rates dropped below 3%, and unexpected shutdowns were virtually eliminated. The service life of wear parts increased by more than 50%, reducing downtime and ensuring continuous and stable equipment operation. The maintenance work not only met the customer’s production requirements, improving efficiency and stability, but also transformed the workshop environment, achieving safe, efficient, and environmentally-friendly production.

Backed by the strength of its parent company, NMS, GIS brings together a team of expert maintenance personnel to offer tailored, high-level maintenance services. They provide fully customized maintenance plans and full lifecycle solutions to ensure optimal equipment performance, helping customers reduce costs, increase production, and gain a competitive edge in the market.

Looking to the future, GIS will continue to deepen cooperation with customers, focusing on daily maintenance as well as lifecycle performance optimization and upgrades. We remain committed to helping customers achieve safe production, efficient operation, and sustainable, eco-friendly development, working together to create a brighter future.