GIS can send experts to the construction site, provide the best maintenance plan, inspect and maintain equipment regularly and prevent major problems. GIS provide full life cycle service and performance solutions. We can provide packaged, customized and other levels of maintenance services. Meanwhile, we can provide process support to maximize the performance of the equipment.

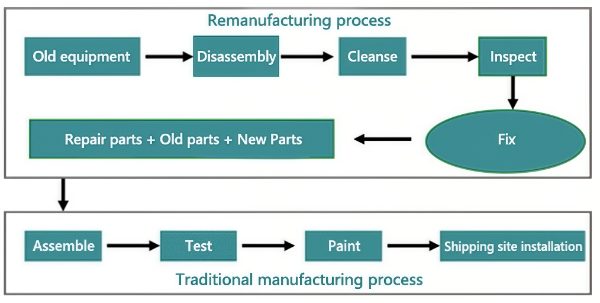

GIS can provide remanufacturing business for customers. Remanufacturing means continuing to use parts that are not damaged, and for parts with local damage, we use advanced surface engineering technology and other means to remanufacture it, so that it can continue to be used. And we take corresponding measures for different failure causes, prolong the service life of the machine. Explore the potential added value in waste products, this is the purpose of the remanufacturing business.

| Single machine data of a project | ||

| Crude ore: metamorphic granite and sandstone | ||

| Before maintenance | After maintenance | |

| Working system (hours) | 24 | 24 |

| Monthly working time (hours) | 400 | 530↑ |

| Monthly yield (tons) | 180000 | 225000↑ |

| Cost per ton (yuan/ton) | 1.22 | 0.89↓ |

| Monthly maintenance time (days) | 7-8 | 5↓ |

A variety of customized transformation and upgrading solutions based on the actual needs of customers, such as upgrading the whole machine, the control system and the use of wear-resistant parts to upgrade devices to the latest technical level for higher yield, reliability and safety, and more convenient maintenance.

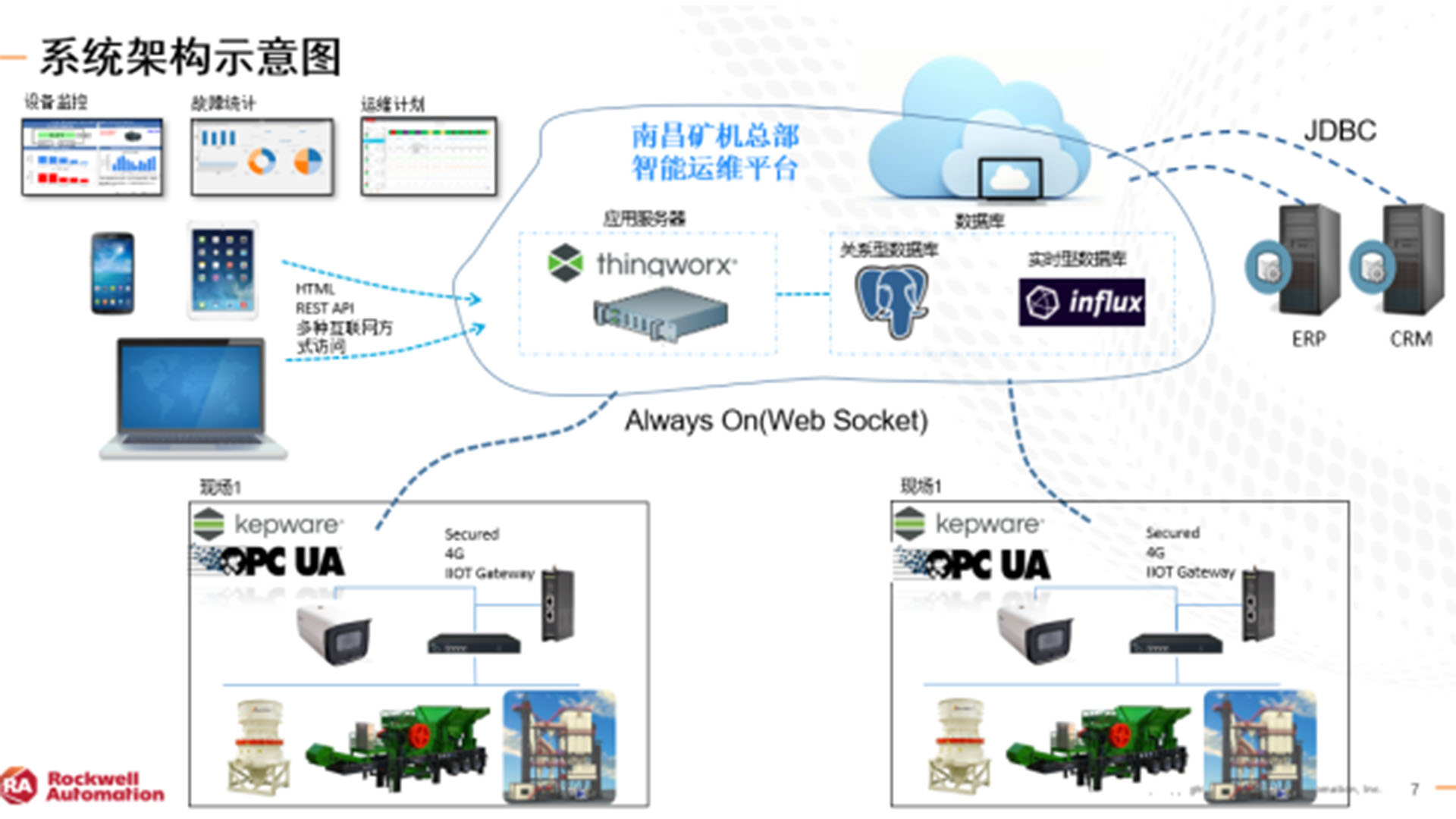

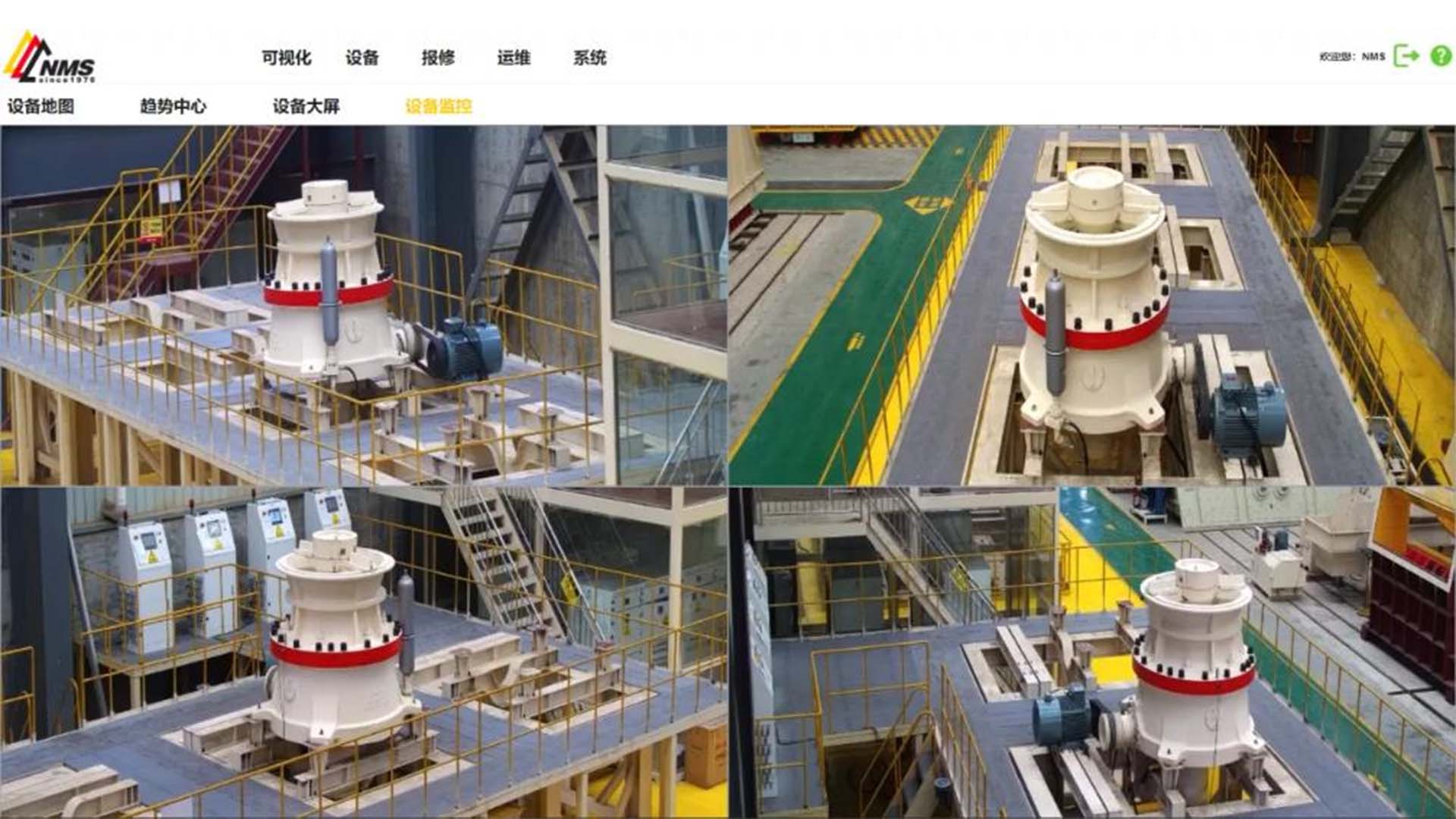

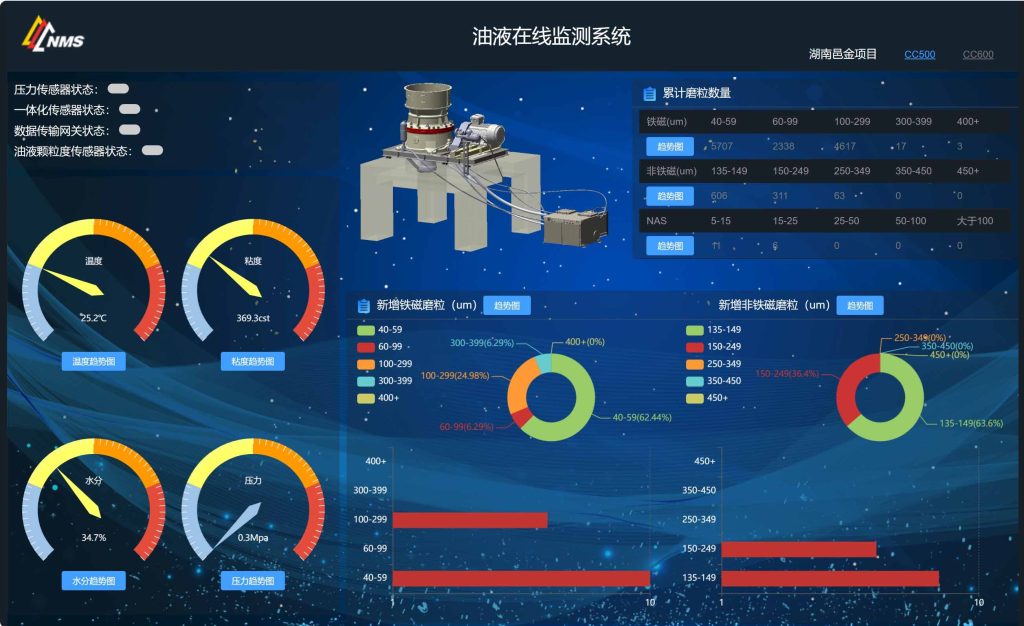

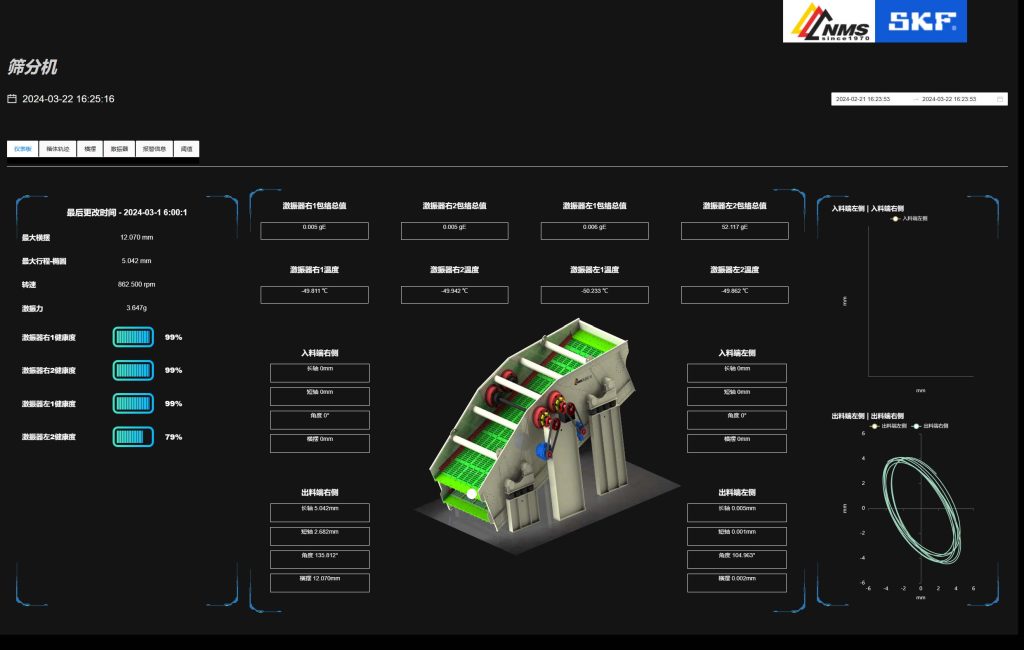

We have a special laboratory for testing ore properties, and make simulation calculation through FlowSheet Designer software independently developed by Swedish R&D Center to provide optimized process and process services, select the most suitable equipment and parts, avoid risks for cost reduction and efficiency improvement. The self-developed simulation analysis software can be used to provide optimization of crushing chamber. By adjusting the parameters including the lining plate of crushing chamber, discharge port, eccentric distance, speed, an appropriate crushing chamber is designed to fully improve the crusher yield and prolong the service life of wearing parts. By integrating performance monitoring, intelligent detection and diagnosis, O&M management and remote service, our intelligent O&M management platform provides continuous monitoring of parameters of host equipment during operation through artificial intelligence and big data analysis so that the equipment can be timely maintained before downtime to avoid huge economic losses to customers due to downtime and help customers get their advantages in competition.

GIS Engineering can provide customers with professional technology, production, process, and other aspects of consulting services in the mining industry. These consulting services can help enterprises solve various technical problems, improve production efficiency, optimize process flow, etc.

GIS provides customers with comprehensive and tailored training programs to help improve the connection among personnel, equipment and production and operation objectives.

Through this training service, customers can better understand the product, improve work efficiency, enhance team collaboration ability, and enhance the overall competitiveness of the company.

Meanwhile, GIS provides regular inspection services for customers to ensure the continuity of production and operation in advance.

GIS work with the customer’s first-line production staff to carry out equipment routine maintenance and fault training meeting

Company Address:

Nanchang City, Jiangxi Province Wanli Hongwan Avenue 300 research center