Recently, Jiangxi Gold Intelligent Service Engineering Co., Ltd. (GIS), a subsidiary of Nanchang Mineral Systems Co., Ltd. (NMS), once again earned high praise from its clients for outstanding product quality and professional, efficient after-sales service.

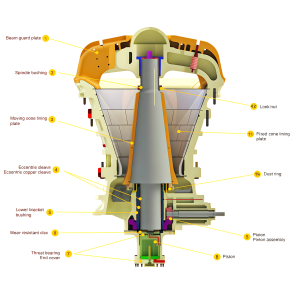

At the production site of a major iron ore project in Sichuan Province, a set of liners supplied by GIS was installed on a gyratory crusher from a well-known international brand. After 11 consecutive months of operation, the liners remained in serviceable condition, demonstrating exceptional durability. When the equipment approached its scheduled maintenance window, the client proactively requested replacement. GIS’s after-sales team responded immediately and efficiently replaced the liners and associated spare parts, ensuring stable and uninterrupted operation of the production line.

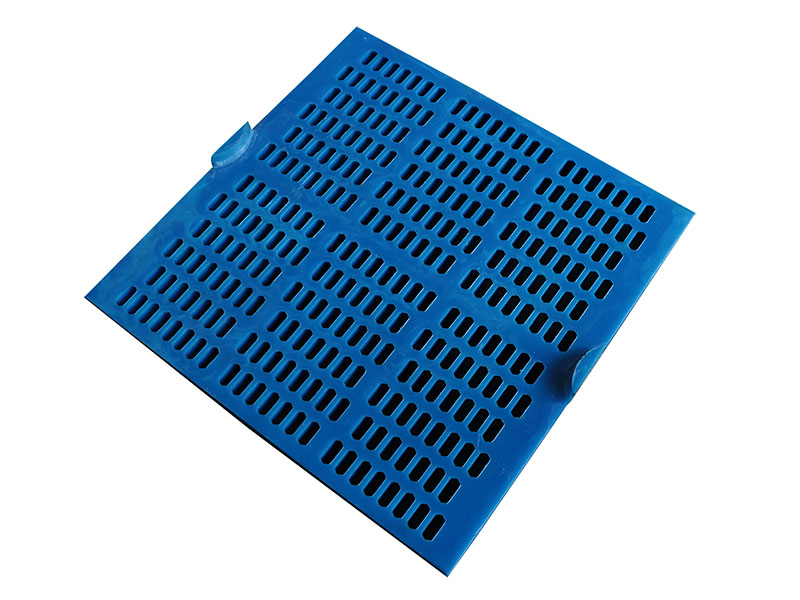

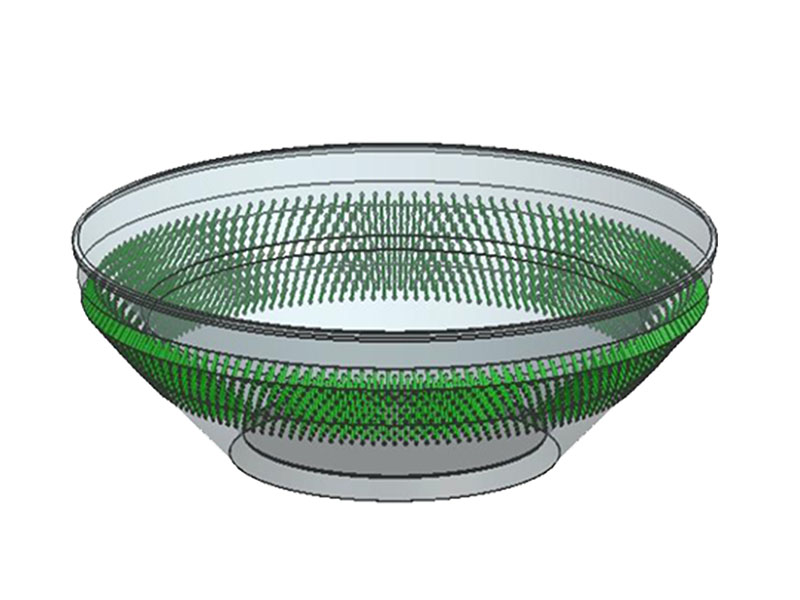

These liners, developed by GIS specifically for harsh mining conditions, are high-performance wear parts manufactured with innovative materials and precision processes. They demonstrate industry-leading performance in wear resistance, impact resistance, and service life. According to client feedback, the system operated continuously at a capacity of 2,400–2,600 t/h over the 11-month period. GIS’s liners consistently maintained excellent performance. Compared to the client’s previous high-manganese steel liners, GIS’s solution extended liner life by 10% to 37.5%, reducing downtime and maintenance costs while supporting efficient production. This real-world data validates GIS’s strong R&D capabilities and customer-oriented design philosophy.

In addition to the mantle and concave liners, GIS also supplied all other key components for the gyratory crusher, including arm liners, main shaft bushings, and eccentric bronze sleeves. Beyond high-quality domestic spare parts, GIS demonstrated strong technical support capabilities—having previously helped the client improve the crusher’s protection and control systems. The next step will be chamber optimization to further enhance capacity and deliver greater economic value.

Upon receiving the replacement request, the GIS service team activated its rapid response mechanism. Equipped with specialized tools, the technical engineers promptly arrived onsite to inspect wear on the removed liners and other parts, while assessing the overall equipment condition. Meanwhile, upon delivery of the new spare parts, GIS’s service engineers provided hands-on guidance to onsite staff, ensuring precise installation and successful commissioning. The entire process was executed efficiently, reducing the maintenance downtime from the originally estimated 20 days to just 15 days. During service, the team also provided operational optimization advice and technical training to the project personnel, further enhancing the client’s self-maintenance capabilities.

The project lead commented: “GIS gives us peace of mind with their product quality, but their service truly moved us. From early-stage technical consulting to post-installation support, every step has been professional and meticulous. The 11-month service life exceeded our expectations, and the high-efficiency replacement process proved GIS’s commitment to customer success.”

This case fully illustrates GIS’s premium product performance and professional service standards. As a key subsidiary in the mining equipment sector, GIS always puts customer needs first. Through its global service network, 24h*7days emergency response mechanisms, and customized spare part supply strategies, GIS supports NMS in building a complete service system from product delivery to full lifecycle management.

Looking ahead, GIS will continue to drive innovation, stay customer-centric, and enhance its integrated product and service solutions. By helping clients reduce costs and boost efficiency, GIS contributes to the sustainable, high-quality development of the global mining industry.