Recently, Jiangxi Gold Intelligent Service Engineering Co., Ltd. (GIS), a wholly-owned subsidiary of Nanchang Mineral Systems Co., Ltd. (NMS), successfully signed a RMB 96 million (approx. USD 13 million) Operation & Maintenance (O&M) contract with a mining company in Hunan Province. According to the agreement, GIS will deploy dedicated equipment and personnel to deliver ten-year comprehensive O&M services for a newly constructed molybdenum ore crushing production line, including equipment operation, maintenance, and lifecycle management. The total contract value is approximately RMB 96 million (approx. USD 13 million).

This signing represents a significant milestone in NMS’s strategic transformation from a traditional equipment manufacturer to an integrated “equipment + service” solution provider. Since its establishment in 2021, GIS has focused on delivering full-lifecycle services for mining customers, covering spare parts supply, complete equipment maintenance, and production line operation and maintenance. Its mission is to help customers improve productivity, reduce operating costs and failure rates, and achieve both higher capacity and efficiency.

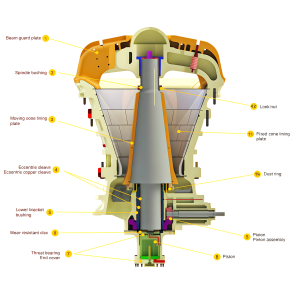

GIS has always adhered to a customer-centric philosophy, building a global service network and implementing a 7×24-hour rapid response mechanism. By offering tailored spare parts solutions and precise maintenance services, GIS has created a comprehensive service system spanning from product delivery to full-lifecycle management, with its technical capabilities proven in multiple projects. For example, in a large iron mine in Sichuan, GIS’s liners were successfully applied to an internationally branded gyratory crusher, achieving 11 months of stable operation with excellent performance and exceeding the expected service life. GIS also supported the customer with equipment protection and control system upgrades, earning trust in domestic wear parts through professional and efficient service.

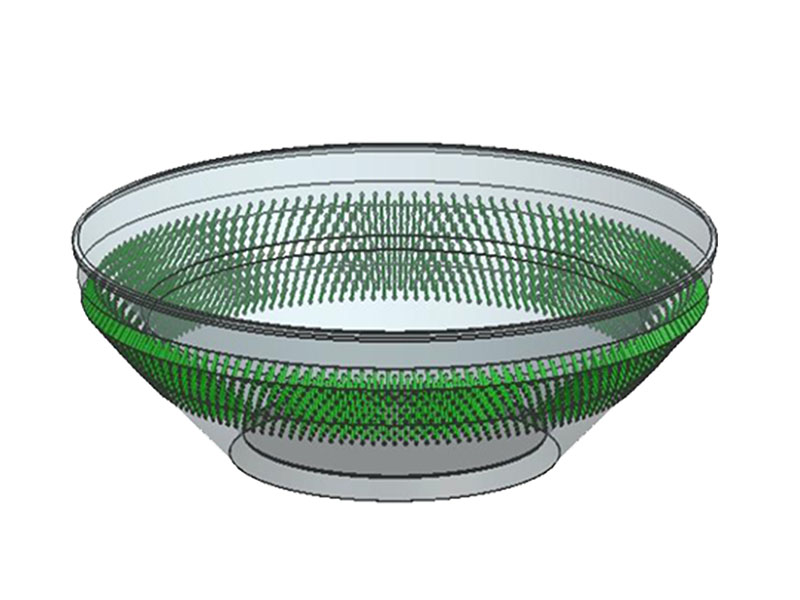

The liners supplied by GIS were successfully applied to a well-known imported gyratory crusher.

The liners supplied by GIS were successfully applied to a well-known imported gyratory crusher.

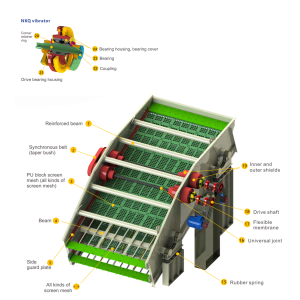

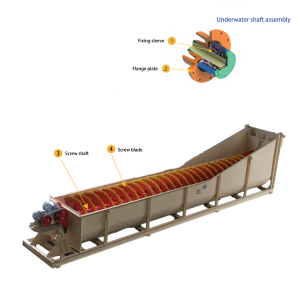

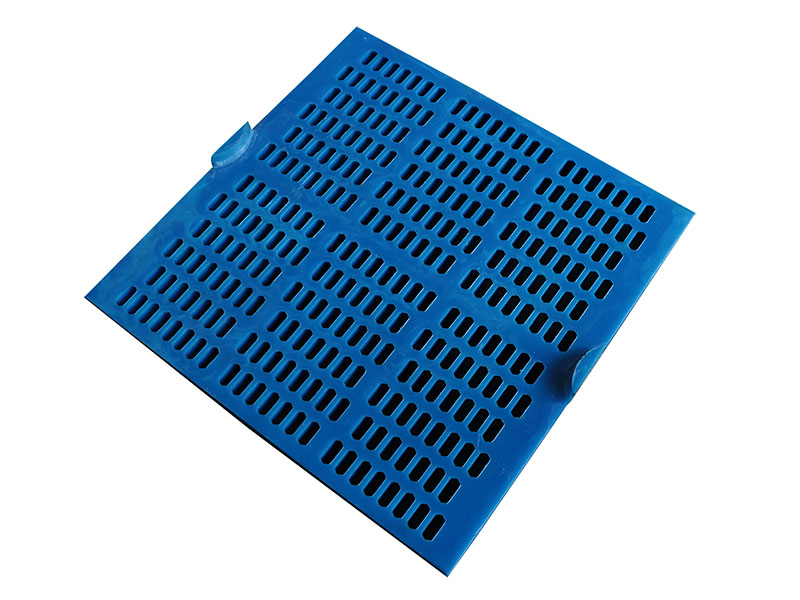

In the field of equipment maintenance and process optimization, GIS has demonstrated outstanding capability. At a polymetallic mine project in Chenzhou, Hunan, GIS formed a team of senior experts to conduct a comprehensive on-site assessment and delivered a customized maintenance solution integrating safety, efficiency, and environmental protection. Through rock sample testing and analysis, the team redesigned the process flow, optimized crusher chamber profiles, and upgraded wear part materials, significantly extending the service life of key components and increasing hourly throughput. By adding environmental protection devices and upgrading electrical systems, the production line achieved one-button start/stop, remote monitoring, load optimization, fault early warning, and automated diagnostics, effectively reducing labor costs. The line ultimately stabilized at 350–400 TPH, meeting the concentrator’s daily requirements with only 12 hours of single-line operation, dramatically reducing O&M costs. Equipment failure rates dropped below 3%, effectively eliminating unexpected shutdowns, and wear part service life increased by more than 50%

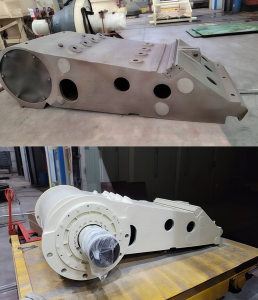

Additionally, GIS stands out in the field of mining equipment remanufacturing. Leveraging NMS’s nationwide service network and top domestic and international technical talent, GIS follows a rigorous scientific process—including inspection, cleaning, disassembly, testing, solution design, remanufacturing, and final inspection—to ensure that remanufactured equipment performs at or above the level of new machines. To date, GIS has successfully completed multiple remanufacturing projects for imported equipment, earning high praise from users and broad market recognition.

Comparison of equipment parts before and after repair

This successful signing demonstrates strong market recognition of GIS’s professional O&M service capabilities and will serve as a benchmark case in the mining aftermarket service sector, greatly boosting its market expansion and brand building. Meanwhile, the execution of this contract is expected to significantly increase NMS’s main business revenue, strengthen its brand influence in the metal mine crushing production line O&M market, and inject powerful momentum into the long-term development of the company’s “equipment + service” strategy.